Generally, the Dip Operator is responsible for hand dipping parts twice, then loading and unloading parts into the producer for the automated dipping process. The Dip Operator also makes slurry for parts to be dipped, and performs start of shift checks and setup on all equipment.

Dip Team Member

Department: Dip

Manager/Supervisor: Section Leader, Production Supervisor

Essential Duties and Responsibilities

- Inspect parts for any defects

- Look up correct dip process according to traveler documents

- Complete the hand dip process:

- If applicable, hand brush logo with ceramic before dipping

- Hand dip the part into liquid ceramic

- Use rainfall sander to cover ceramic coating with sand

- Complete the automated dip process:

- Load parts on spider (movable rack) to be placed in the producer

- Set program using software on the CD2

- Unload completed parts onto carts with traveler documents

- Clean spiders as needed

- Complete all necessary paperwork

- Clean equipment and area after completing shift

Minimum Educational and Work Qualifications

- High school diploma or GED/High School Equivalency

- Experience working in a manufacturing or production environment

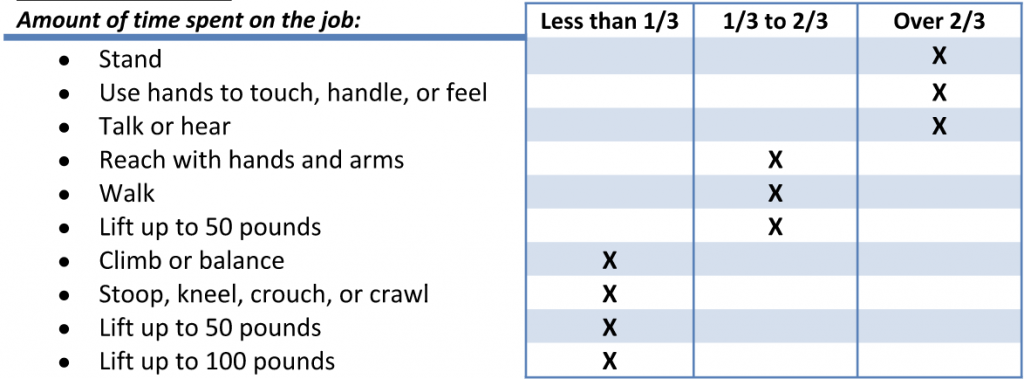

Physical Requirements

Environmental and Working Conditions

These statements are intended to describe the general nature and level of work being performed by individuals assigned to this position. They are not intended to be an exhaustive list of all duties, responsibilities and skills required of personnel so classified.